Cutting Machines

Kinetic has many solutions to meet your needs, whether you are a small fabrication shop looking to cut out one-off parts or you are looking to cut heavy plate and process many parts non stop, Kinetic have a machine that can do it all. Cutting/milling/drilling/tapping and oxy cutting all in one, allowing one machine to cut, bevel and tap parts.

High quality production machines

Click on the images to find out more

If your looking for a fast, quick and smart machine the class leading K1200 is for you. With the ability of plasma and oxy cutting as well as basic drilling.

High accuracy, dual driven fast cutting machine. Heavy duty with lots of options for cutting including plasma, Oxy, triple Oxy and pipe cutting also able to drill and tap holes. K2500 creates a standard in the industry.

Production cutting machines that do it all

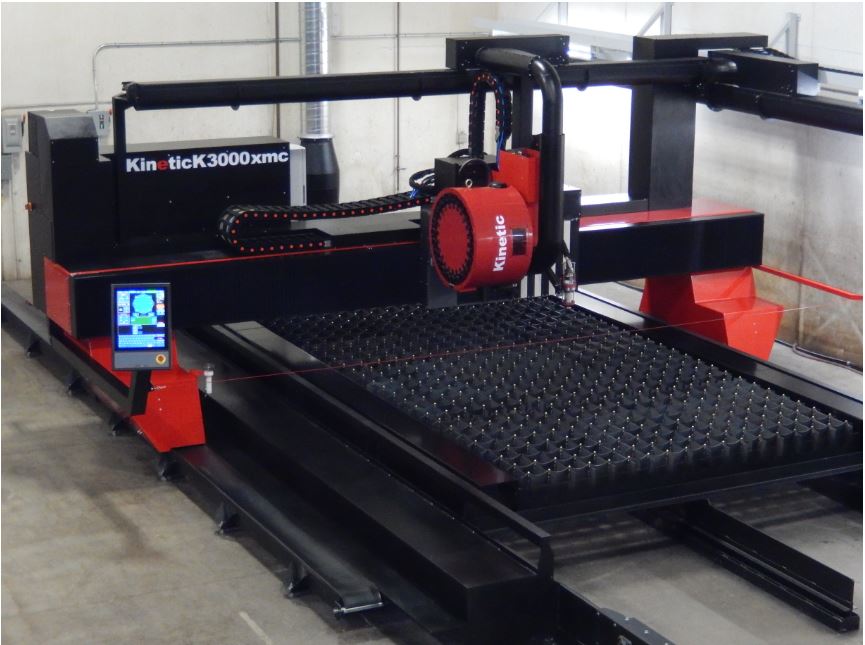

The K3000xmc is a machine that can do it all with a 24 bit tool changer and dual torch cutting potential. A machine that will allow mass production of parts.

A highly innovative machine with accurate cutting and drilling. The K4000XMC is the machine capable of plasma cutting up to 3 inch thick plate and drilling 2 and a 1/2 inch holes.

This is the machine to do it all, bevel cutting, multiple torches, milling and drilling. The K5000 is a processing giant with the CAT 50 spindle. With 3 second automatic tool changes, it speeds up the cutting process to make your production fast tracked.

Automated handling machines

The K5200 is much like its brother, the K5000, however it adds automated robotic part removal. The addition of the automatic part removal fast tracks your unloading time and improves you work shop cutting. This is the highly innovative, smart heavy duty cutting machine that sets itself apart from other machines.