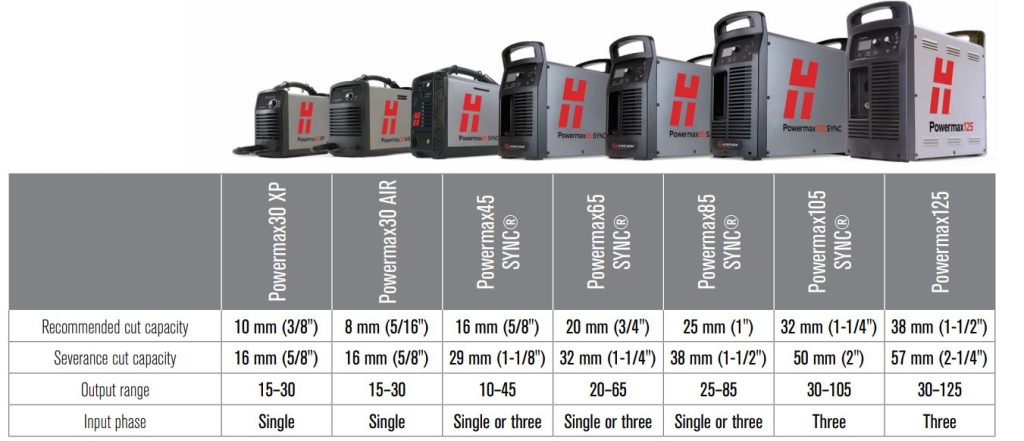

Powermax Plasma Range

High performance industrial products for every cutting and gouging need

For metal workers who need to easily and reliably gouge and cut metal up to 38 mm (1-1/2″), Powermax® is a line of seven portable, professional-grade plasma systems that are designed for maximum productivity. Unlike other metal removal methods or competitive plasma brands, industry-leading Powermax systems allow customers to tackle any job by offering the most extensive manual and automated metal cutting and gouging capabilities.

Powermax 30 XP

The Powermax30® XP is a highly portable plasma cutter designed to handle a wide range of jobs. A unique “two-in-one” design provides high-power capability for thick metal cutting, as well as FineCut® consumables for detailed, thin metal cutting. In addition to cutting any electrically conductive metal, such as mild steel, stainless steel, or aluminum, this 30-amp plasma cutter can also gouge metal. The Powermax30 XP boasts dual-voltage capabilities. In addition to 240 V, you can plug it into a standard household socket and use as a 120 V plasma cutter.

Powermax 30 Air

Despite its small size, the Powermax30® AIR delivers big performance. This small air plasma cutter — the smallest, lightest handheld plasma cutter in its class — includes its own built-in air compressor. That’s right, it’s a small plasma cutter with a built-in compressor so you can use the Powermax30 AIR anywhere there’s single-phase power. Just plug it in, attach the work clamp and you’re ready to cut. It’s even dual-voltage. You can use it as a 120 V plasma cutter or at 240 V. Regardless of which power input (120 V or 240 V) you choose, we think you’ll agree the Powermax30 AIR is the best plasma cutter with built-in compressor available today.

Powermax 45 SYNC

For metal workers who want the most versatile system available to gouge, cut, and mark, Powermax45 SYNC delivers the best return on investment with a patented single-piece cartridge, up to 5x longer consumable life, and greater cutting power than higher-amperage competitors.

Powermax 65 SYNC

The Powermax65 SYNC® is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for gouging and recommended cutting up to 20 mm (3/4″). Featuring automated system process set-up via advanced RFID-enabled SmartSYNC® torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax65 SYNC maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

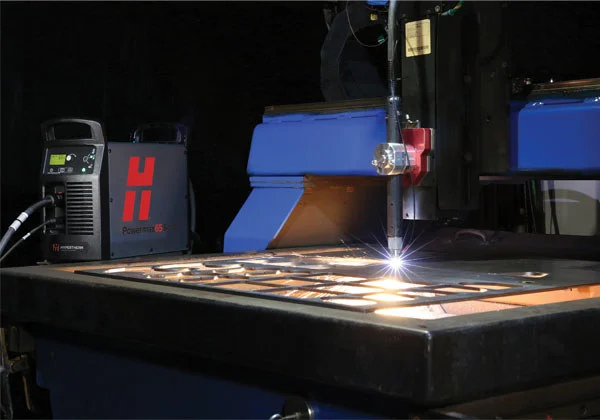

Powermax 85 SYNC

The Powermax85 SYNC® is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for gouging and recommended cutting up to 25 mm (1″). Features automated system process set-up via advanced RFID-enabled SmartSYNC® torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax85 SYNC maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

Powermax 105 SYNC

The Powermax105 SYNC® is a next-generation, professional-grade air plasma cutter that dramatically simplifies system operation for gouging and recommended cutting up to 32 mm (1-1/4″). Features automated system process set-up via advanced RFID-enabled SmartSYNC® torches, and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax105 SYNC maximizes productivity through reductions in downtime, optimized cut quality performance, and streamlined consumable inventory management.

Powermax 125

Delivering maximum power and performance for air plasma, the Powermax125® plasma system cuts thick metals fast. Able to make short work of the toughest cutting and gouging jobs, the system offers a 100% duty cycle, a 25 mm (1″) mechanized pierce capability, and fast gouging metal removal. It also gives you the latest technological innovations, such as Smart Sense™ technology to automatically adjust the gas pressure. Eleven Duramax® Hyamp™ torch styles provide versatility for hand cutting, portable automation, X-Y table cutting, extended reach cutting, and robotic cutting and gouging.

Hypertherm Powermax cartridge consumable platform

With its revolutionary single-piece design, the new cartridge consumable for Powermax® systems will change the way you cut and gouge metal forever. Your consumable inventory management will be streamlined. Select your cartridge and with a simple twist onto the torch you’re ready to go.

Benefits of Hypertherm Powermax cartridges

Easy to use

SmartSYNC® torches with the cartridge automatically set the correct amperage and operating mode, eliminating setup errors.

Easy to identify single-piece cartridges are color-coded by process to eliminate parts mix-up and simplify consumable inventory management.

End-of-life detection lets the operator know when it’s time to change the cartridge.

Simplified operation minimizes downtime, troubleshooting, waste, and training time.

Upgrading to the Hypertherm cartridge platform is easy for Powermax45 XP/65 /85 /105 systems via a torch adapter for Duramax® torches.

Versatile

Tackle a wide range of jobs with easily interchangeable torch styles and application-specific cartridges for various types of cutting and gouging.

Time-saving torch controls allow the operator to adjust the amperage on the fly and change cartridges and applications without returning to the power supply.

Access cartridge data for performance tracking, analyzing usage patterns when used on SmartSYNC torches.

Specialty cartridges for gouging, HyAccess, FlushCut™ and FineCut® extends the capabilities of Powermax systems

Torch compatibility

Fully compatible with all SmartSYNC torches, providing automated process set-up and data transfer to the system

Available cartridge reader accessory pairs with Powermax SYNC smartphone app to analyze performance data such as starts, transfers, and arc-on time

Limited functionality with Duramax and Duramax® Lock torches (found on Powermax45 XP/65/85/105)

Requires separate torch adapter (part number 428951)

Does not provide automated process set-up or data transfer

MaxPro 200

The MAXPRO200 plasma cutting system achieves impressive cut speeds, consistent cut quality and exceptional consumable life with air or oxygen plasma gas. Optimized cutting parameters are automatically set and controlled in one step for easy operation. Engineered for heavy-duty, high capacity mechanized and handheld cutting and gouging, the MAXPRO200 delivers reliable performance across a wide range of industrial applications. Smart Sense™ technology automatically adjusts the gas pressure according to cutting mode and torch lead length. It also detects electrode end-of-life, automatically turning off power to the torch to prevent potential damage to other parts or to the work piece.